Product Description:

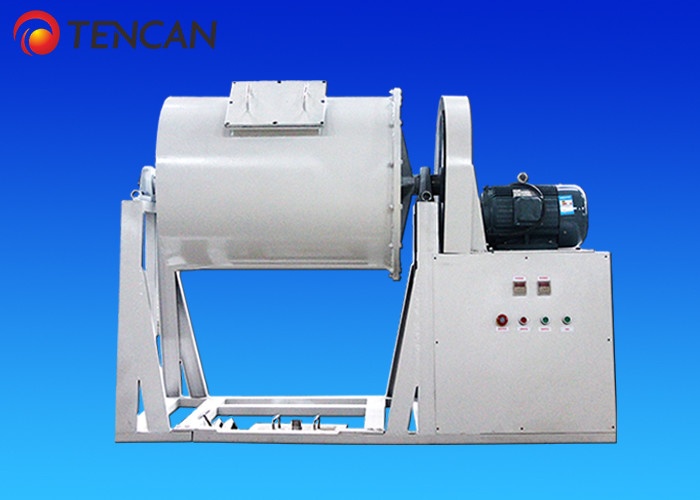

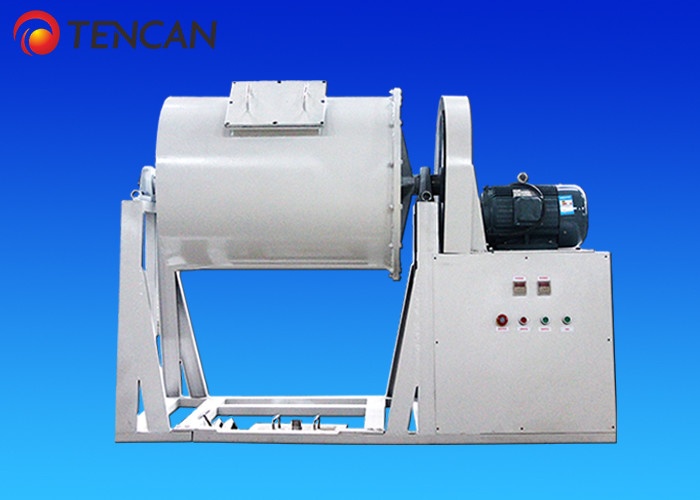

Tencan's Rolling Ball Mill is designed to grind materials into fine

powder of up to 300-500 mesh size. This ball mill is powered by a

220v voltage motor, and can operate at a rotation speed of

20-60rpm. The feed size of this ball mill is between 1-10mm,

allowing for precise and efficient precision grinding. This Rolling

Ball Mill is a perfect choice for those looking for superior

grinding results that are reliable and efficient.

Overview:

Lab roll mill is a kind of equipment used for ultra-fine grinding

and mixing for laboratory and small batch production. The machine

is preferred equipment for scientific research, education,

experiment and production due to its advantages such as elegant and

fashion design, compact structure, easy operation, high efficiency,

and uniform granularity. It is widely applied to industries of

electronic material, magnetic material, biological medicine,

ceramic glaze, metal powder, nonmetallic minerals, new materials, and etc.

Working Principle:

When mill works, the grinding media and the materials inside the tank are rotated to a certain height. Due to the gravity, they fall down

from the tube wall. Materials are crushed by impact action of the grinding media,

friction and shearing action of grinding media’s rolling and

sliding.

Features:

1. Compact structure, easy operation

2. High efficiency and uniform granularity

3. Milling pot in different size can be put on the driven rubber

roller within a certain range by means of adjusting space between

the rubber rollers.

4. It is convenient to change pots and suitable for both wet and dry grinding.

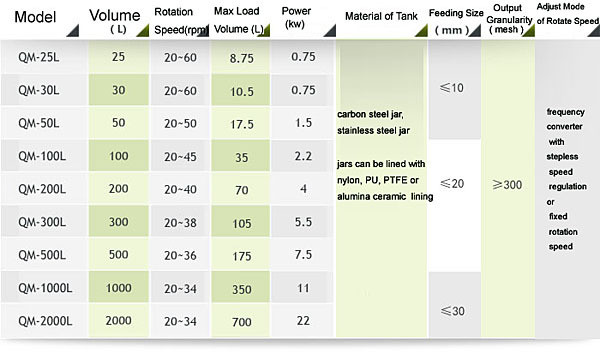

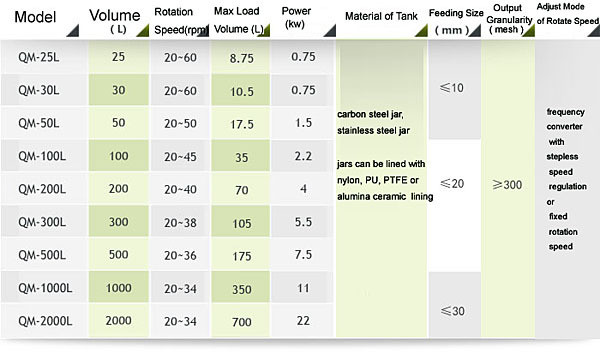

Technical Parameters:

Accessories:

Besides rolling ball mill machines, we provide all kinds of roll

mill jars,like stainless steel mill jar, zirconia mill jars,

alumina ceramic mill jars, nylon mill jars, PU mill jars, PTFE mill

jars, and etc. Further, we also provide stainless steel mill balls,

zirconia mill balls, alumina mill balls, agate mill balls, tungsten

mill balls, etc.

| References About Grinding Medias & Materials |

Materials of

Grinding Media | Hardness

(Mohs) | Features |

| Zirconia Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high

temperature resistance. |

| Stainless Steel Balls | ≥6.0 | Wear-resistant, general corrsion resistance, high temperature

resistance. |

| Agate Balls | ≥7.0 | Super wear-resistance, used for medicine,food and other materials

which can not be contaminated with metal, corrosion, and high

temperature resistance. |

| Alumina Balls | ≥8.5 | Wear-resistant, corrsion resistance and high temperature

resistance. |

| Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, without any impurity, corrosion & high

temperature resistance. |

| Matching Solutions for Mill Jars & Balls |

Items | Agate Balls | Alumina Balls | Stainless Steel Balls | Zirconia Balls | Tungsten Carbide Balls |

| Agate Mill jar | √ | | | | |

| Corundum Mill Jar | ▲ | √ | | ▲ | |

| Stainless Steel Mill Jar | | | √ | | |

| Zirconia Mill Jar | | ▲ | | √ | |

| Nylon Mill Jar | ▲ | | | √ | |

| PTFE Mill Jar | √ | | | ▲ | |

| Polyurethane Mill Jar | √ | | | ▲ | |

| Tungsten Carbide Mill Jar | | | | ▲ | √ |

| √ means: most suitable ▲ means: suitable |

Recommendation of These Accessaries:

| Recommendation For Matching Solutions About Mill Jars & Materials |

| Categories of Materials | Recommended Mill Jars |

| Soil and other Materials which are not allowed with any impurity | Agate mill jar |

| Metal & nonmetal materials which are not allowed with any impurity | Zirconia mill jar |

| High hardness materials like diamond, tungsten carbide | Tungsten carbide mill jar |

| Strong add & alkali materials or other materials at high

temperature | PTFE mill jar |

| Iron ore materials with lower impurity sensitivity | 304 Stainless steel mill jar |

| Pigment or other materials with later process under high

temperature | Nylon mill jar |

| Aluminum materials like ceramic glaze | Corundum mill jar |

| Electronic materials like lithium battery | Polyurethane mill jar |

| Easily oxidized materials or some special materials which need to

be protected under special atmosphere. | Vacuum mill jar |

After Sales Service:

1) One year guarantee for whole machine except of ball mill jars and balls.Some accessories we have 18-36 months warranty.

2) We shall make prompt response to any problem about the machine

within 24 hours if you have.

3) We shall provide 6-day 8-hour services for all our clients and

subscribers, and shall provide trouble-shooting solutions until the fault is completely

eliminated.

4) If the machine is found any fault or problem, please do not

hesitate to notify us the details about faults, caused reasons and status. We shall do our great efforts to

solve according to following terms:

a. Common faults:

Common faults refer to failure of non critical parts or improper

configuration that effects partial operation or leads to Inconvenience of machine operation. We shall

solve such problems by email or posting parts by courier.

b. Serious faults:

Serious faults refer to failure of key parts or improper

configuration that influence running or operating of machine widely. We shall firstly diagnose reasons of

faults by email or phone, then shall send replacement of parts by courier, until solve the

problems. Courier freight shall be for our account within quality warranty period.

FAQ: